Materia Viva: everything flows.

Materia Viva embodies our vision of sustainability, creativity and a corporate mission. Materia Viva is our sustainability manifesto and encompasses all paper with recycled content: nine families of fine paper regenerated from recycled materials.

With each sheet we reduce the impact of our supply chain on the environment in order to maximise the impact of creativity on the world.

Our ‘making progress’ philosophy continuously pushes us to search for innovative and alternative solutions to improve the performance and aesthetics of our products and to make them more sustainable, without compromise, and thus to serve as a point of reference for the entire ecosystem – brands, printers, converters, graphic designers and suppliers – who, like us, feel the responsibility to make a change.

Materia Viva

Chapter I

ROOTS

21 ranges of paper made of recycled fibres. 21 ranges of materials. Discover their essence and their roots, as well as their characteristics which share a common origin – the recycled materials they come from – but which are all different.

Explore on the website

Chapter II

METAMORPHOSIS

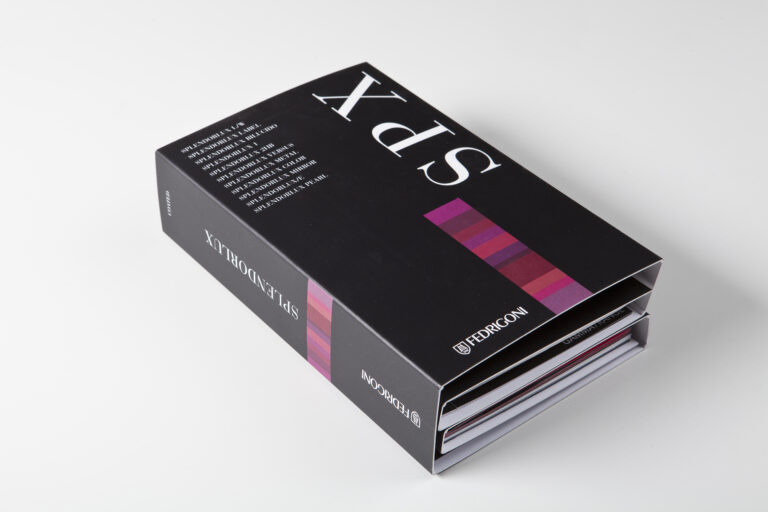

From food to cosmetics. From fashion to retail. From jewelry to luxury. From corporate to personal care. Paper acquires characteristics that broaden its areas of application and use. Creative and functional solutions, equivalent to plastic in design and technical use.

Explore on the website

Chapter III

COMING SOON

Thinking about new products

Our target by 2030 is to have 100% of recyclable products certified by third parties.

Find out also about Fedrigoni Self Adhesives commitment to sustainability

Recycled Material

We produce specialty paper, both coated and uncoated, which can consist of between 40% and 100% recycled material derived from post-consumer waste. Our challenge is to continue to do so while maintaining the aesthetic characteristics and high performance of our products as much as possible.

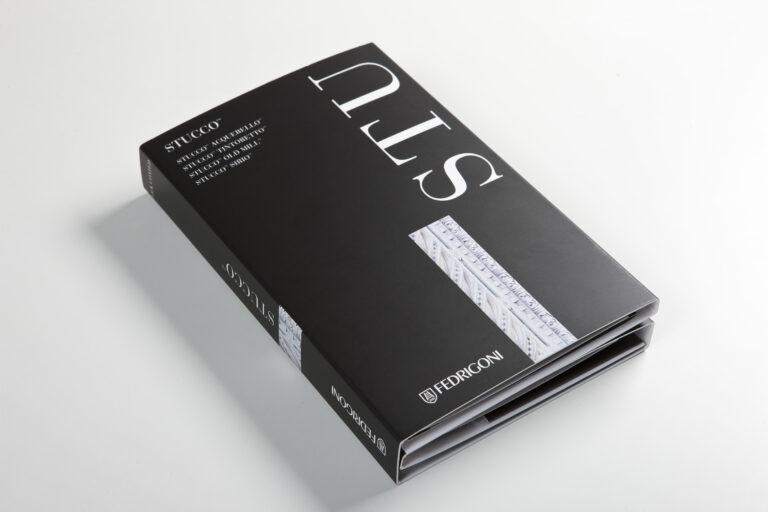

Packaging solutions

We experiment with new sustainable and advanced solutions integrated into the paper, thus minimising the complex elaborations and processes undergone by brands and consumer goods. There is an extraordinary aesthetic strength to allowing naturalness to shine through.

Fibre alternatives

Cotton, hemp, linen, annual fibres and selected recycled fibres: we work, study and strive to combine pulp with alternative fibres in order to achieve a circular economy and economic sustainability. Innovation and creativity also become a sensory experience.

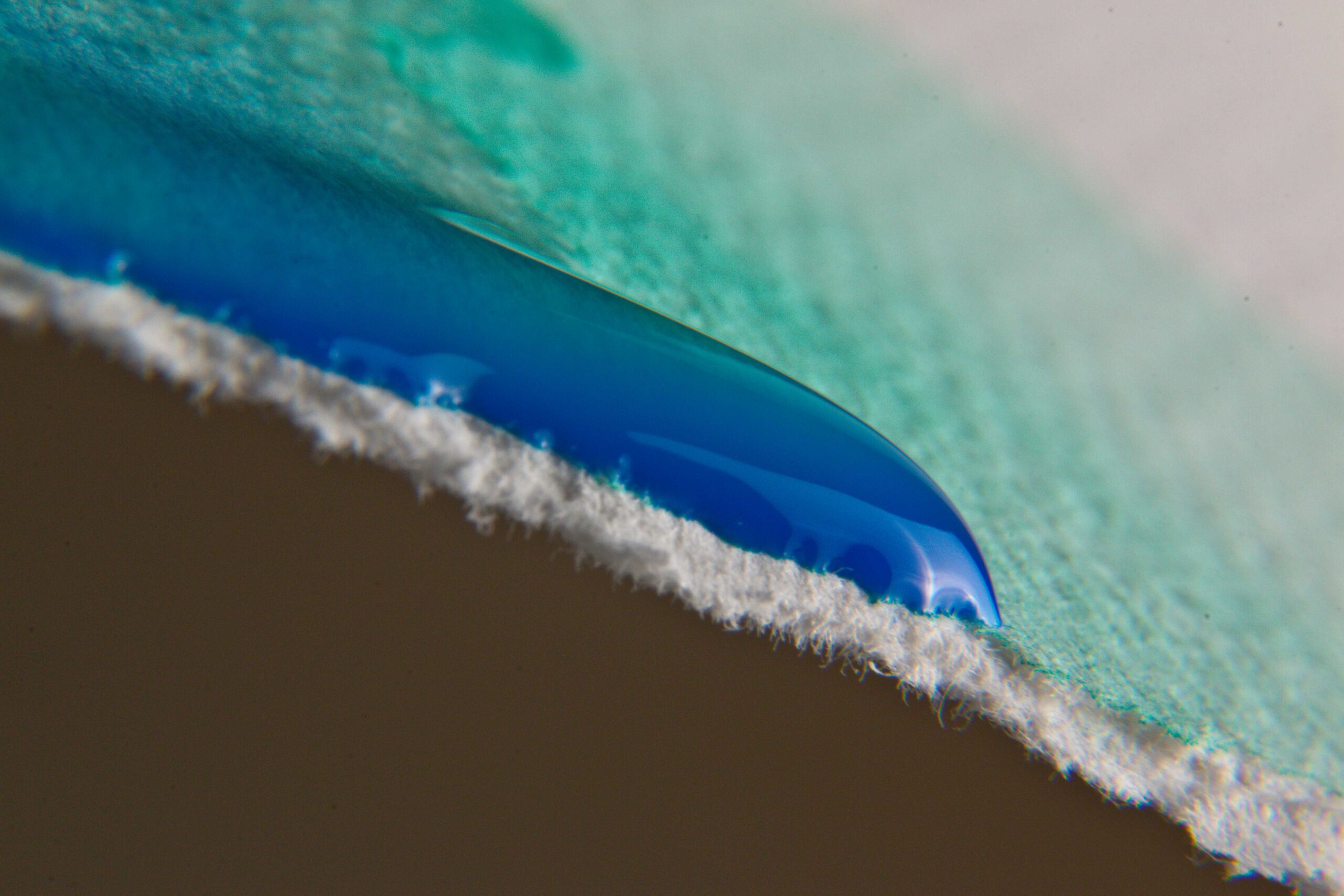

Plastic to paper

Paper is an exceptional material. At Fedrigoni, we are convinced that it has a disruptive role in reducing the use of plastic, which is why we are creating paper products and paper solutions to achieve this. Examples of this include paper with scratch-resistant treatment, which avoids protective plastic wrapping and lamination; high-thickness paper for resistant and environmentally-friendly gift packaging.

Fed | Lab

Fed | Lab is our innovation hub, where the Next Generation Paper is born. Here, innovative ideas take shape and become new products with a high technological component and advanced ESG features intended to support our current and future commitment to the circular economy. It serves as an incubator of talents and projects from all areas of the company and from outside, which helps us to ‘make progress’ in the P2P (plastic to paper) transition and to offer our customers better and more innovative products every day.

Find out more about what happens at Fed | Lab

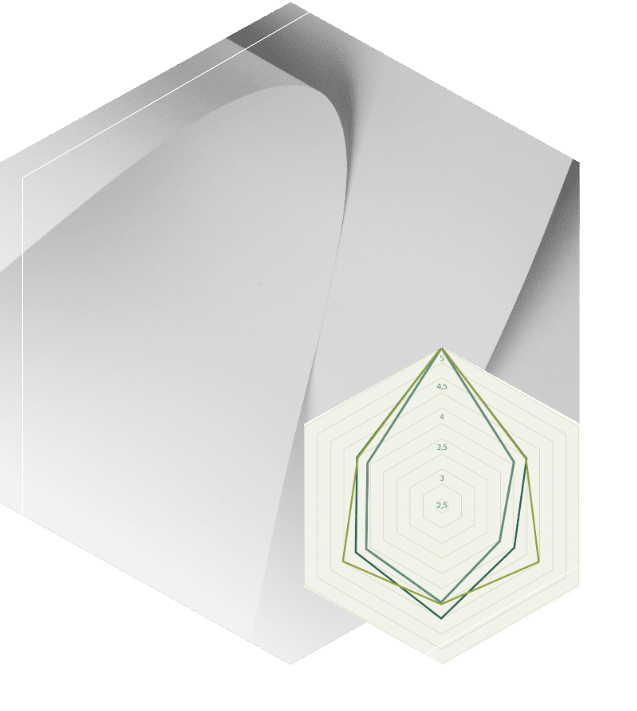

Recycled Tool

Not all recycled paper is the same. At our paper mills we scientifically verify the technological performance and environmental impacts compared to pure pulp paper in order to establish the best uses for each kind. We share our results.

Everything you ever wanted to know about recycled papers, explained with reliable scientific data.

Compare the performance of paper with recycled content

Discover more about our sustainability journey

At Fedrigoni, sustainability is the ability to make progress every day in a measurable and transparent way, which is the challenge we undertake with the help of all our people and our two cores: the Paper Division and the Self-Adhesives Division. Today, our production processes are inspired by the circular economy, eco-design and innovation, and step by step this brings us ever closer to the ambitious climate and social targets we have set for ourselves.

Find out about the Group commitment to sustainability